We produce spools for welding wire and state-of-the-art machines

We are an all-Italian company and have been producing fully recyclable, high-performance spools for steel welding wire since 1998.

We also design machines for the mass production of steel spools, which we sell worldwide.

We export our products and provide direct customer service on the machines sold all around the globe.

Our

Our vision

Vision

is inside this video

Click on the image to watch it

Our

Our mission statement

Mission

is our promise to the customer

New Spool aims to confirm itself on the market as the manufacturer of the best-performing spools, constantly ensuring eco-compatibility and increasingly innovative technical specifications.

We offer a wide range of products because our customers are increasingly demanding and constantly looking for an innovative, high-performance, and eco-friendly product.

We use recyclable materials in many steps of the production.

We aim to reach those markets where our steel spool isn’t predominant yet.

Our development pursues both financial goals and focuses on a sustainable growth for the planet.

Our story goes back a long way

In a small Swedish town called Gavle, the two Gustafsson brothers, owners of the company GAVLE TRADE AB, jointly designed and built the prototype of a machine to produce a new type of metal spool intended for winding welding wire.

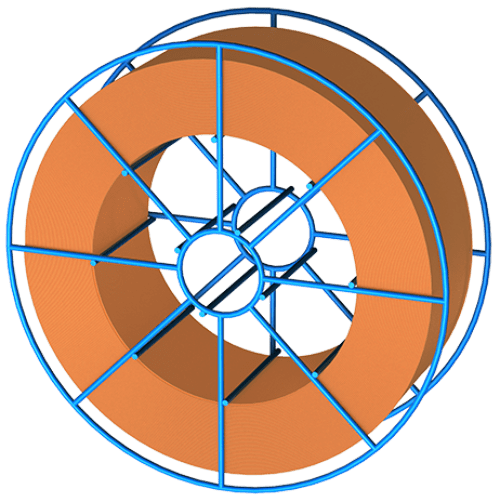

From the very first moment, this spool has been better performing, more solid, and more accurate than all the others on the market.

Suitable for precision layer winding at high speed on semiautomatic and automatic machines.

Back in the 1998 the two brothers needed a partner who believed in their idea and was willing to invest.

The meeting with Remo Zadra, a European welding inspector, well known in the sector, was crucial for their future.

Thanks to the partnership with GAVLE TRAD AB, New Spool becomes the world’s first BS300 spool manufacturer.

In 1998 New Spool srl was founded

From the garage full of winning ideas

In the beginning, our headquarters was nothing but a little garage located in a small village in Val di Non, Trentino.

It was right there that our dream began to come together: we began producing and marketing a metal spool for welding wire, “the BS300.”

Our constant desire to innovate, along with an unwavering commitment, make us a solid and strongly progress-oriented company.

to the 4,500 square meters plant

Today our two production halls have a covered area of more than 2,500 square meters and a total area of 4,500 square meters.

At the beginning there were just the 3 of us, today we are 25 people.

Our challenge has always been to make people understand the technical value of a product that is qualitatively superior to the ones with the same purpose already on the market.

From the garage full of winning ideas

In the beginning, our headquarters was nothing but a little garage located in a small village in Val di Non, Trentino.

It was right there that our dream began to come together: we began producing and marketing a metal spool for welding wire, “the BS300.”

Our constant desire to innovate, along with an unwavering commitment, make us a solid and strongly progress-oriented company.

to the 4,500 square meters plant

Today our two production halls have a covered area of more than 2,500 square meters and a total area of 4,500 square meters.

At the beginning there were just the 3 of us, today we are 25 people.

Our challenge has always been to make people understand the technical value of a product that is qualitatively superior to the ones with the same purpose already on the market.

We fulfill high environmental and quality standards

We guarantee our customers a highly sustainable manufacturing process and product.

We work with a 100% recyclable material

Anything that "is not a spool" becomes scrap material given to companies that recycle it

Not only spools:

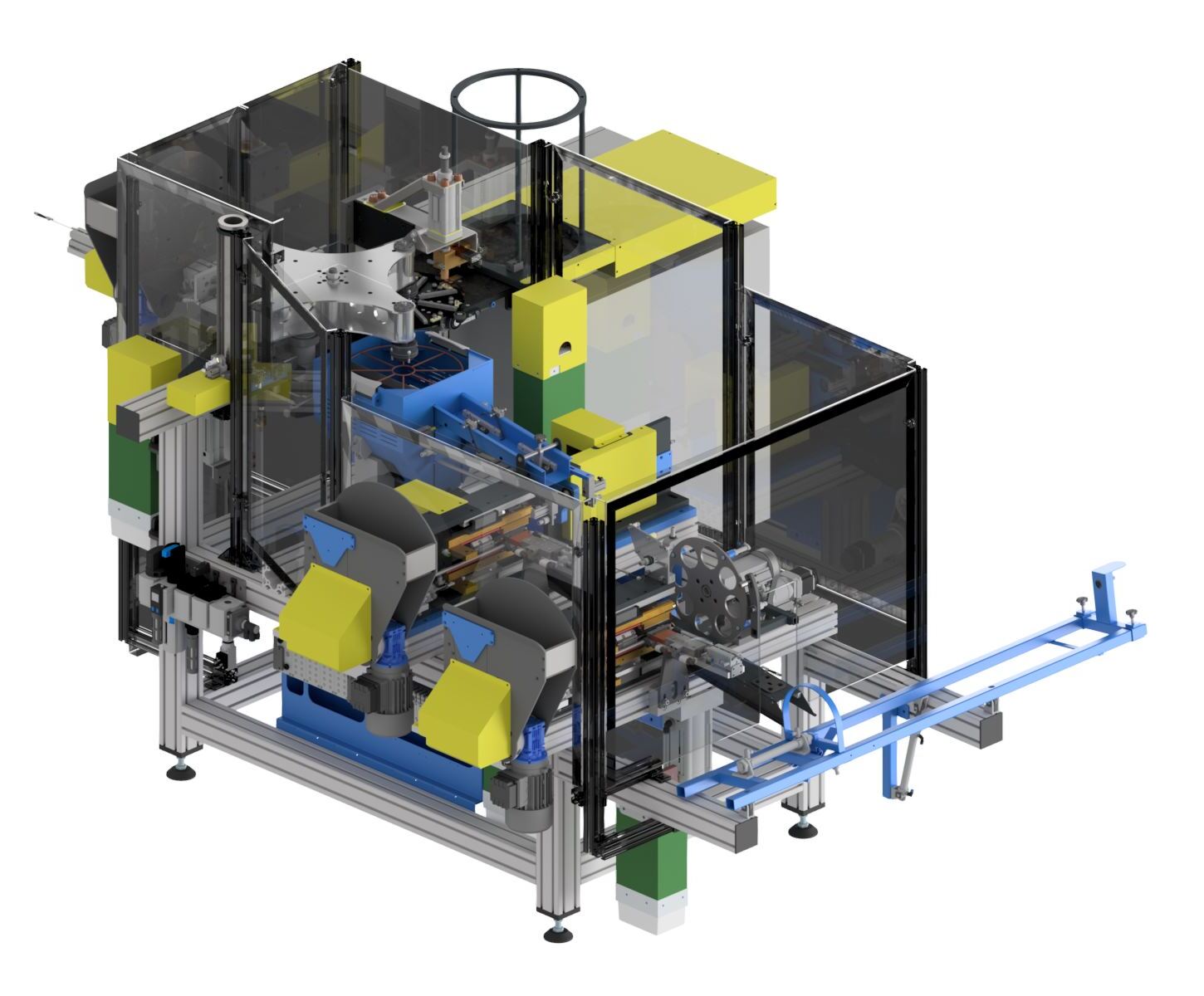

We design machines for the production of welding wire spools

Over time we have become the leading company in the production and marketing of welding wire spools.

At first, we produced a hundred thousand spools a year, now more than four million.

Since 2009 we have designed and marketed machines for mass production of different steel spools.

Our planning aims to constantly improve the performance of our machines.

For this reason, we provide customer service and sell spare parts for the machines we sell worldwide.

New Spool in the world

We aim high

Today, the BS300 spool is present in more than 25 countries around the world: we are able to reach every inhabited continent.

We work in Turkey, United States of America, Mexico, Brazil, and Vietnam to name a few, and we are ready to increase our production even more.

Since 2014 we have decided to expand our product range to all types of metal spools. This has also enabled us to optimize costs and logistics organization.

But with feet on the ground

In 2015 we achieved an important recognition: the certifications for quality and environment. A strategic achievement for us, in a market that has identified New Spool as synonym of quality.

Our spool has thus become the “eco- friendly spool“.

We think that every small step toward protecting the environment is a step toward the future. Therefore, we want to introduce our spool to countries where plastic is still very much in use.

We aim high

Today, the BS300 spool is present in more than 25 countries around the world: we are able to reach every inhabited continent.

We work in Turkey, United States of America, Mexico, Brazil, and Vietnam to name a few, and we are ready to increase our production even more.

Since 2014 we have decided to expand our product range to all types of metal spools. This has also enabled us to optimize costs and logistics organization.

But with feet on the ground

In 2015 we achieved an important recognition: the certifications for quality and environment. A strategic achievement for us, in a market that has identified New Spool as synonym of quality.

Our spool has thus become the “eco- friendly spool“.

We think that every small step toward protecting the environment is a step toward the future. Therefore, we want to introduce our spool to countries where plastic is still very much in use.

Our quality

is certified

Our team

To achieve high quality standards in the production of welding wire spools, we rely on a competent and motivated staff working on the continuous improvement of processes and products.

Fabio Manca

CEO & Managing Director

Marina Zadra

Chair Woman

Cristina Zadra

Quality Enviroment Manager

Cristina Salazer

Sales Manager

Umberto Pegorin

Sales Market Development Manager

Liviu Stetco

Technical Manager

What people say about us

The words of our satisfied customers are and will always be our best calling card.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.